The 12kV Indoor SF6 Switch-Disconnector FL(R)N36 Load Break Switch (LBS) is a robust, double-break rotary load switch that utilizes SF6 gas as both an insulating and arc-extinguishing medium, making it ideal for 12kV power distribution systems. Each switch is permanently sealed with SF6 gas at 0.4 bar, ensuring reliable performance and maintenance-free operation. The switch is versatile in installation, with options for both vertical and horizontal mounting. In typical ring main unit installations, a horizontal steel partition is used between the cable and busbar compartments, isolating the busbar from the cable joint for enhanced safety during operation and maintenance.

The FLN36-12 indoor high-voltage SF6 load switch can be combined with other electrical components to enable comprehensive control and protection, supporting the safe and efficient operation of industrial and mining facilities, civil power supply systems, and secondary substations. For enhanced protection, the FLRN36-12kV load switch-fuse combination unit is specifically designed to match the protection characteristics of transformers, making it especially suited for ring network power supply applications.

Use Conditions

1. Ambient air temperature: upper limit +40℃, lower limit -15℃.

2. Environmental humidity: The daily average relative humidity is not greater than 95%, and the monthly average relative humidity is not greater than 90%.

3. Altitude: The maximum altitude of the equipment installation site is 2000m.

4. Earthquake: The earthquake intensity does not exceed 8 degrees.

5. The surrounding air should not be significantly polluted by corrosive flammable gases, water vapor, etc. There should be no frequent severe vibrations.

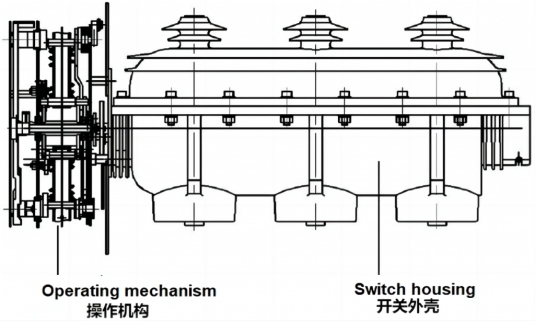

Operating Mechanism

The spring operating mechanism of the load switch and its combined electrical appliances is divided into single spring operating mechanism and double spring operating mechanism. The FLN series load switch equipped with a single spring operating mechanism is mainly used for the incoming and outgoing line control unit. The FLRN series load switch-fuse combination appliance equipped with a double spring operating mechanism is mainly used for transformer protection units.

Installation and Debugging

1. Before installation and debugging, be sure to read the instruction manual carefully and make the following preparations: First, check whether there is any damage to the appearance. Damaged products should be stopped immediately. The second step is to remove contamination on the surface of the product due to transportation or other reasons.

2. When the operating mechanism and the switch body are assembled, it must be ensured that they are reliably fixed, and their connecting parts should be reliably fixed on the operating shaft of the switch body, and the components connecting the load switch should also be reliably fixed on the switch body. on the switch.

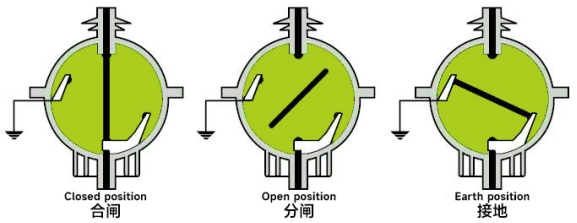

3. After the installation is completed, confirm that the load switch is in the opening position, insert the operating handle into the grounding operating hole on the upper end of the panel, and turn the handle 180 clockwise. To perform ground closing, rotate the handle 180 degrees counterclockwise. Complete the closing of the grounding switch.

4. When performing the closing operation, first confirm that the load switch is in the opening position, then insert the operating handle into the load switch operating hole at the lower end of the panel, and rotate the operating handle 180″ clockwise to complete the closing operation of the load switch.

5. During the process of moving the load switch from the closing position to the opening position, use the K-type operating mechanism, insert the operating handle into the operating hole of the load switch, and rotate the handle counterclockwise 180″ to perform the opening operation; for the A-type operating mechanism, Operating mechanism, press the opening button to open the load switch, check through the observation window whether the position of the switch is correct, and whether the corresponding observation instructions meet the requirements.

6. Note: The grounding or load can only be closed when the switch is in the open position!

Maintenance and Care

Under normal use conditions where the environment meets the requirements of the installation and operation instructions, the switch body is guaranteed to be maintenance-free for 20 years. Due to environmental differences, necessary inspection and maintenance work on the load switch is still required.

l According to the working environment, conduct appropriate visual inspection of the insulation cover between June and December, and remove dirty and damp surfaces.

l Carry out lubrication and operation inspection of the operating mechanism 1 to 2 times a year to ensure normal operation.

l For load switches equipped with pressure gauges, the readings of the pressure gauges should be checked from time to time.

l When a fault current passes through the load switch fuse combination appliance and one phase fuse blows, all three phase fuses must be replaced. When replacing, the grounding switch must be closed first before replacement, and ensure that all three-phase fuses are installed in place.