In medium-voltage power distribution systems, the most commonly used ring main units (RMUs) include SF6 gas-insulated RMUs, solid-insulated RMUs, and environmentally friendly gas-insulated RMUs. However, due to the environmental impact of SF6 as a greenhouse gas and the challenges associated with recycling solid insulation materials, the use of SF6 gas-insulated and solid-insulated RMUs faces limitations. With the growing emphasis on sustainable and environmentally responsible development, fully insulated, eco-friendly gas RMUs that align with modern environmental standards are poised for significant growth opportunities.

The EcoAir-HBX-15.6/24kV 630A series represents a new generation of “fluorine-free and low solid waste” green circuit breaker switches and gas-insulated RMUs designed as sustainable alternatives to traditional SF6 systems.

These environmentally friendly circuit breakers feature a high-strength, integrated longitudinal beam that houses the vacuum arc extinguishing chamber. This robust design offers reliable performance and simplifies installation and maintenance. A unique integrated isolation spindle ensures precise control over opening, closing, and grounding operations, minimizing the need for additional transmission mechanisms and reducing operating force. The main shaft, constructed from epoxy fiberglass, delivers excellent mechanical strength and insulation performance. Additionally, silicone umbrella skirts are added between phases to enhance creepage distance. This circuit breaker is suitable for both sealed air chamber RMUs and conventional pressure metal-enclosed RMUs.

Utilizing a combination of environmentally friendly gas insulation and vacuum interruption, this solution provides superior performance with minimal maintenance requirements. The gas-sealed primary circuit is altitude-independent, maintenance-free, and highly adaptable to different environmental conditions. Its compact cabinet size allows for efficient use of space, making it suitable for power grids, large-scale industries, rail transit, commercial buildings, and more.

This product is ideal for 10-24kV medium voltage distribution networks, both indoors and outdoors, supporting energy distribution through flexible configurations, including top expansion, side expansion, and common box solutions (up to three units). The unit boasts a high parts commonality rate (over 90%) between upper and lower isolation options, ensuring exceptional stability, versatility, and full compliance with industry type test standards.

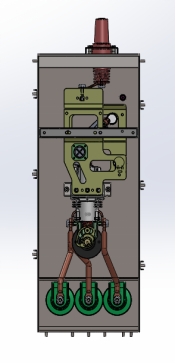

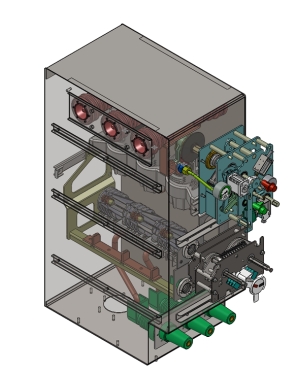

Internal Structure of Lower Isolation Dry Air Insulated Switchgear

Switch Cabinet Side Expansion Plan

Switch Cabinet Top Expansion Plan

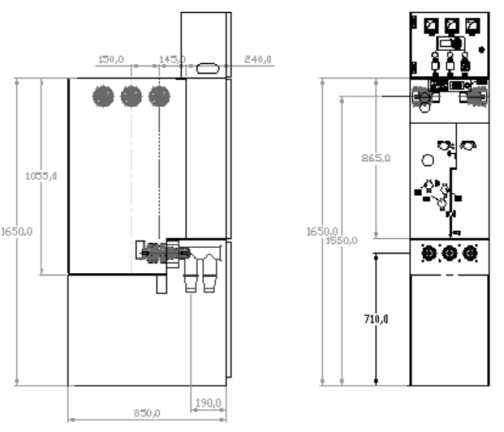

Installation Notes

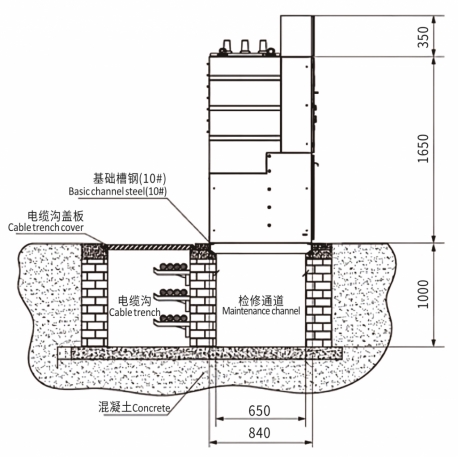

This product should be installed on the embedded channel steel on the concrete platform, and the platform base should be enough to bear the total weight of the equipment.

Note: The foundation channel steel for secondary pouring is buckled, and the unevenness per meter is no more than 1mm. The switch cabinet is fixed on the foundation channel steel and the basic load of the welded switch cabinet is allowed to be 500-700kg/unit.

Foundation and Overall Dimensions (mm):

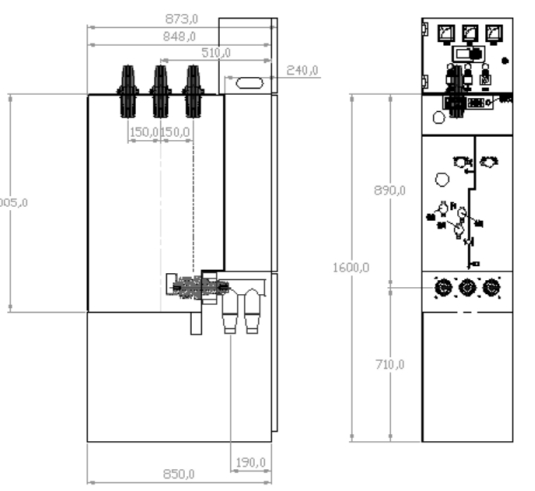

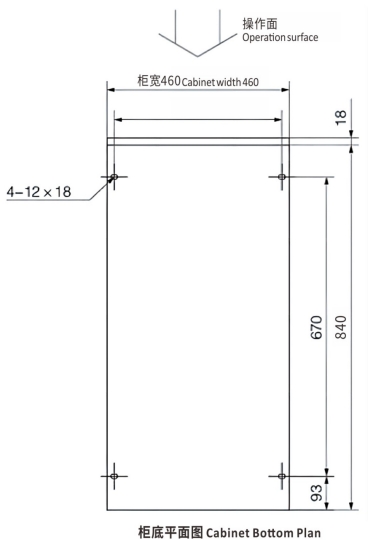

Switch Cabinet and Appearance Installation Dimensions (mm):

The height of the switch cabinet is 1650mm (without independent instrument room). If independent instruments are required, the switch height is 2000mm. The standard configuration cabinet depth is 850mm.

Use Conditions

EcoAir-HBX-15.6/24kV 630A is generally operated/serviced under normal indoor conditions and complies with IEC 62271-1 and GB3906. The specific conditions are as follows:

1. Ambient temperature.

Maximum temperature: +40℃.

Maximum temperature (24-hour average): +35°C.

Minimum temperature: -40℃.

2. Humidity. Maximum average relative humidity measured over 24 hours: 95%.Maximum average relative humidity measured over one month: 90%.

3. The maximum altitude of installation without reducing gas pressure is 1500 meters. When the installation altitude exceeds 1500 meters, please contact pre-sales technology.

4. Operation must comply with the requirements of IEC62271-1 and GB3906 standards. For special operating conditions, the end user and the manufacturer must reach an agreement. If special harsh operating environments are involved, the manufacturer must be consulted. For example, when electrical equipment is installed at an altitude above 1,500 meters, the atmospheric pressure will decrease, causing the air box to bulge.

Product Maintenance

All components inside the 15.6kV/630A are maintenance-free during the declared product life.

The isolation and grounding positions can be observed to provide safety guarantee for operation and cable construction.

The system loop is completely isolated from the atmosphere, and a special arc pressure relief channel is designed on the air box to ensure the safety of operators and equipment.

The mechanical part is located outside the air box and behind the front panel, making it easier to operate and replace. The surface of the mechanical part has undergone anti-corrosion treatment, and its movable parts have been lubricated before leaving the factory, which can meet the use of the product life cycle. In extreme environments (dust, sand and dirt) inspection, maintenance and, in some cases, replacement may be necessary.